Services

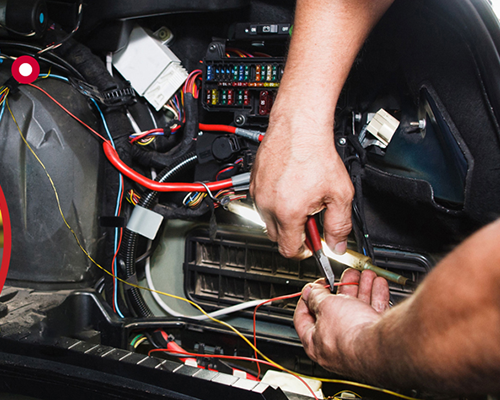

Electrical Works

A Standard Operating Procedure (SOP) for servicing a vehicle’s electrical system ensures safety, efficiency, and thoroughness. The vehicle’s electrical system includes the battery, alternator, starter motor, wiring, fuses, and various electronic components. Here’s a detailed SOP for vehicle electrical work service:

Vehicle Electrical Work Service SOP

1. Safety Precautions

- Park the vehicle on a flat, level surface.

- Use wheel chocks to prevent the vehicle from rolling.

- Wear safety goggles and gloves.

- Disconnect the negative battery terminal to avoid electrical shocks and short circuits.

- Ensure you have the proper tools and equipment, including a multimeter, wiring diagrams, and protective equipment.

2. Initial Inspection

- Visual Inspection:

- Check for visible signs of wear, damage, or corrosion on wires, connectors, and electrical components.

- Inspect the battery terminals for corrosion and ensure they are securely connected.

- Functional Inspection:

- Test all lights (headlights, taillights, brake lights, indicators) and electrical accessories (radio, wipers, power windows) for proper operation.

3. Battery Service

- Testing:

- Use a multimeter to measure the battery voltage. A healthy battery typically reads between 12.4 and 12.7 volts when the engine is off.

- Perform a load test using a battery tester to check the battery’s ability to hold a charge.

- Cleaning:

- Clean the battery terminals and cable connectors using a mixture of baking soda and water to remove corrosion.

- Apply a thin layer of petroleum jelly or battery terminal protectant to prevent future corrosion.

- Replacement:

- If the battery fails the tests, replace it with a new one of the correct size and specifications.

4. Alternator and Charging System Service

- Testing:

- Start the engine and measure the voltage across the battery terminals. It should read between 13.8 and 14.5 volts, indicating proper charging.

- Use a multimeter to check the alternator output and ensure it meets the manufacturer’s specifications.

- Inspection:

- Inspect the alternator belt for wear, cracks, or improper tension. Adjust or replace the belt as necessary.

- Replacement:

- If the alternator fails the tests or shows signs of failure (noisy bearings, burnt smell), replace it with a new or rebuilt unit.

5. Starter Motor Service

- Testing:

- Perform a voltage drop test on the starter circuit to ensure there is minimal resistance.

- Check the starter motor operation by turning the key and listening for proper engagement and rotation.

- Inspection:

- Inspect the starter motor wiring and connections for looseness or corrosion.

- Replacement:

- If the starter motor fails the tests or shows signs of failure (clicking sound, slow cranking), replace it with a new or rebuilt unit.

6. Fuses and Relays

- Inspection:

- Check all fuses and relays in the fuse box for continuity using a multimeter.

- Replace any blown fuses or faulty relays with ones of the correct rating.

- Functional Check:

- Test the functionality of the components controlled by the fuses and relays to ensure proper operation.

7. Wiring and Connectors

- Inspection:

- Visually inspect all wiring harnesses and connectors for signs of wear, damage, or corrosion.

- Pay special attention to areas where wires pass through bulkheads or near moving parts.

- Repair:

- Repair or replace any damaged wires or connectors using proper automotive-grade materials and techniques (e.g., soldering, heat shrink tubing).

- Secure:

- Ensure all wiring is properly routed and secured away from heat sources and moving parts.

8. Lighting and Electrical Accessories

- Testing:

- Test all vehicle lights and electrical accessories to ensure proper operation.

- Inspection:

- Check the bulbs, sockets, and wiring for damage or corrosion.

- Replacement:

- Replace any burnt-out bulbs, damaged sockets, or faulty electrical accessories.

9. Diagnostic Trouble Codes (DTCs)

- Scan for DTCs:

- Use an OBD-II scanner to check for any stored diagnostic trouble codes.

- Interpret and Address:

- Interpret the codes and address any issues as per the manufacturer’s guidelines.

10. Final Verification

- Reconnect Battery:

- Reconnect the negative battery terminal.

- Functional Check:

- Perform a final functional check of all electrical systems and components to ensure everything is operating correctly.

- Road Test:

- Conduct a road test to verify the proper operation of electrical systems under driving conditions.

Preventive Maintenance Tips

- Regularly inspect and clean battery terminals.

- Test the battery and charging system at least once a year.

- Replace worn or damaged belts promptly.

- Address any electrical issues or warning lights immediately to prevent further damage.

- Follow the manufacturer’s recommended service intervals for electrical system components.

By following these steps, you can ensure that your vehicle’s electrical system remains in good working condition, providing reliable performance and safety.